They’re on almost every product in the grocery store. And there’s a couple ways to get them. What am I talking about? Barcodes. Barcodes help to create the grocery industry’s treasure trove of data. Through quick scans of the codes, you can learn how much of each product is selling, and even find a cheaper price at stores near by.

For many small food business entrepreneurs adding barcodes may be an unnecessary expense – it’s cumbersome, you usually have to get your label custom designed, and it can be expensive.

On the other hand, it’s a necessity to growing your food business, getting your product into major retailers, and becoming a more established company.

Yes, there are pros and cons, but getting barcodes goes far beyond tit for tat. It enters into strategy, sourcing, and design. Let’s dive into these sections further.

Related Reading: 25-Step Plan to Make Your Food Company a Reality

What you’ll learn:

- What Barcodes Mean

- Pros and Cons of Barcodes

- Recycled VS GS1 Barcodes

- How to Test Your Barcodes

- How to Let Stores Know About Your New Barcodes

- Template Downloads

Let’s get started — there’s so much to learn about barcodes!

What Barcodes Mean

When you look at barcodes, you probably think they don’t mean anything, except for serving as the identifier of a unique product. Yes, they do, but they are so much more.

Barcodes contain the SKU (stock keeping unit) for retailers to keep track of their inventory. Without this, they wouldn’t know how much of each product is in stock. And inventory is important to retailers because it’s money that’s tied up in (mostly) physical goods.

The SKU (the long string of numbers) is broken up into three parts:

- Your unique manufacturer’s ID

- Your unique product ID

- Your check digit (the last number)

Let’s look at an example:

In this example, the barcode is read like this:

- Manufacturer’s ID: 020357

- Unique Product ID: 122682

- Check Digit: 2

The manufacturer’s ID is unique to (you guessed it) the manufacturer. This is only if you purchase your barcodes from the GS1 – the official barcode entity. We’ll get into why this is important later.

Your unique product ID corresponds to the product it’s on. For example, our wholegrain mustard has one. So does our horseradish. And each of our mustards. And if our mustards came in different size containers (4oz, 9oz, and 32oz), each product needs it’s own barcode.

Example: You have 10 flavors in 2 sizes. You’d need 20 barcodes. If you then had a case-pack UPC, you’d need 40 barcodes, but that’s terribly confusing. Only have a case-pack UPC is you have a master carton (cases in a box) or it’s requested of you by a major retailer.

And the check digit simply makes sure your barcode is the correct format. This check digit is required for new production information sheets at Whole Foods Markets.

Sounds pretty simple, right?

Let’s look at some pros and cons of getting barcodes:

Pros of Getting Barcodes

Barcodes are essential to get your product into retail.

Your product is ready to go on the shelf

There’s nothing better to a retail buyer than having a product that can go right on the shelf – barcode, nutrition facts, and all. Getting barcodes means they can scan your new product right into your system.

Ready for major retailers (even if you aren’t)

When you’re approached by big retailers, you want to be ready to go. They’ll ask for vendor information and product information immediately. And usually this includes a list of your barcodes. Don’t have them? You can kiss the big purchase order goodbye.

You can keep your own inventory

If you want, you can use your barcodes to keep your own product inventory. While I don’t do that for Green Mountain Mustard, if I had more than 25 products, it could make some sense.

Attention Founders: Download our food business startup kit with business canvas, startup spreadsheets, and exclusive interviews.

Cons of Getting Barcodes

It can be expensive

If you get your own set of barcodes, you’re looking at a $750 setup fee (25 barcodes included). Then you pay the $149 annual fee. This doesn’t include the possible redesign of your labels to fit the barcodes.

Small stores probably won’t use them

The stores that don’t use any barcoding system are likely to be your first retailers. This means they’ll sticker a price – or their own barcode – over your barcode. Kind of makes your expensive barcode useless? Oh well – but it makes you want to get into retailers who have an inventory system, right?

So, in this list the pros outweigh the cons. Are you thinking “Let’s buy some barcodes”?

Hold up!

The decision can get a little more complicated when you decide whether you should buy recycled barcodes or get your own barcodes. That’s next up in the ultimate guide.

Recycled Barcodes vs. GS1 Barcodes

Want your food in retail? You’ll need labels.

UPC Codes are a big decision. Both solutions — recycled and GS1 — have their advantages and disadvantages. Ultimately, it depends on where you want your business to go. Here’s a look at why you’d choose each type of barcode.

Why You Should Choose Recycled Barcodes

They’re inexpensive

100 barcodes costs you $45 at Nationwide Barcode. That’s cheap compared to the GS1. As a startup, you can’t go wrong, but you get what you pay for — recycled barcodes. These aren’t yours. An aspiring entrepreneur bought thousands of barcodes and is simply reselling them to small businesses.

You don’t plan to sell to large grocery stores

If you want to make some extra cash selling a product to small retailers in your state, then you’re probably fine with recycled barcodes. And some retailers may not even require them, so maybe you won’t need them!

You don’t mind them not being in sequence

Let’s face it. Most entrepreneurs are type A. That means we like things in order. Unfortunately recycled barcodes (most of the time) don’t come in order – you could have a different prefix, too – depending on when you buy barcodes and need more. That creates an inconsistency in the retailer’s system.

Plus, the global UPC record-keeping system is going to see your barcodes as someone else’s – whether it’s an old product or not (that’s what recycled barcoded are).

Related Reading: Menu & Recipe Cost Template – Download My Spreadsheet

Where to buy recycled barcodes:

- Nationwide Barcode – 25 for $31.25

- Barcodes Mania – 25 for $25.00

Why You Should Choose GS1 Barcodes

- Many large grocery stores require them

You can’t step foot into large grocery stores like Wegmans, Harris Teeter, and EarthFare without GS1 barcodes. They have you provide your GS1 company prefix on your paperwork for new item submission. There’s no way around it.

- You get your OWN barcodes

I own my own prefix now — specific to Green Mountain Mustard. That’s pretty awesome. And no one else shares that prefix. That means when I have national distribution, I’ll be able to look up sales data on my product — that’s data unavailable to me right now.

- It’s an investment

If you start a food company, you’ve got to be in for the long haul. That means making investments where you need to. One of those is real GS1 barcodes. They run $750 for 25 barcodes and then $150/year for “membership”. Make the investment.

I started with recycled barcodes and made the switch to my own GS1 barcodes 3 years later. I’ve never looked back. It’s helped my product on the shelf at larger retailers and made my company legitimate in the eyes of buyers. And it’s made it a hassle to get my barcodes changed with older retailers.

Ultimately, it’s your decision. I’d recommend GS1 barcodes from the beginning.

How to get your GS1 Barcodes: Head over to the GS1 and get started.

Formatting Barcodes on Your Food Product

Promoting at a local farmer’s market.

Now that you’ve decided to purchase barcodes (recycled or from the GS1), it’s time to put them on your labels. Just a couple things to keep in mind:

- Barcode files tend to come with strange file extensions that require other software to open and format.

- Your barcode can go on either side of your label – the left or right panels.

- Your barcodes can be pretty small

- You barcodes do not have to include the whole bar (ours are cut in half)

- Make sure to test your barcodes (more on that below)

How to Test Your Barcodes

The worst thing to happen to a new food product is to print your labels only to find out the barcodes don’t scan. (Ok, maybe this isn’t the worst thing, but it’s pretty awful) Before you print them professionally, print them on your computer and do one of two things:

- Take them to a retailer. Bring your codes to a retailer and ask them to scan the code. If it beeps, you’re in luck. If you bought recycled barcodes, It may bring up another product in the system, but don’t worry too much about it. If it doesn’t scan, you have to make the coder bigger and/or clearer for the scanner to recognize it.

- Scan them with your smartphone. Download a shopping app or QR reader and scan the barcode. If it beeps, you’re in luck. If it isn’t, make it clear just like above. Oh, and this method is practically free – and saves you the driving time to the store.

Once your barcodes are purchased, integrated into your label, and scanned, it’s time to let your retailers know about your new barcodes. Here’s the process I used:

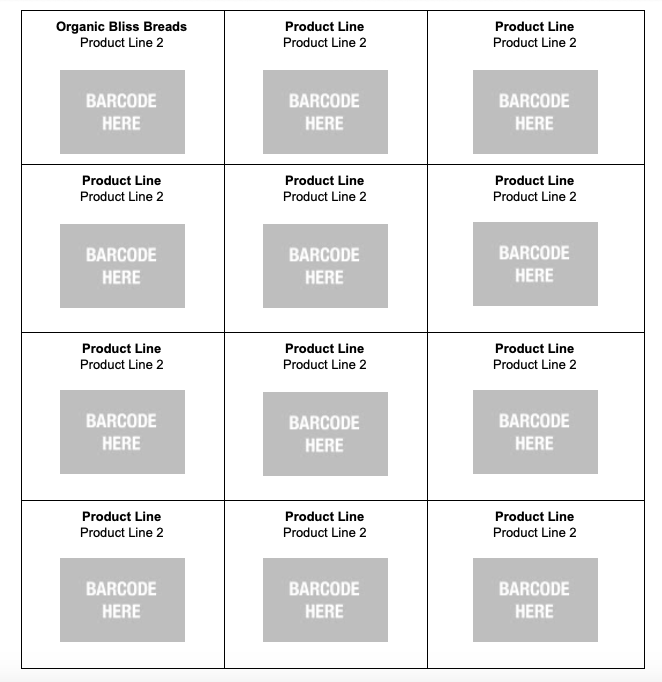

How to Notify Your Retailers:

- Create a Microsoft Word or Google Doc.

- Insert a table that’s 3 columns wide by however many rows you need

- Paste one barcode into each cell

- Include product name and unit size (9oz) below the barcode

- Save the document as a PDF

- Send it to your retailers, distributors, and brokers.

This sheet makes it easier to get your barcodes into their system by providing a quick scan sheet.

Free Barcode Template Download:

Download this UPC barcode template below.

If you’re looking for an editable barcode document, I’ve provided one for free here – no email address required. (Just replace the “Barcode Here” boxes with your own UPC codes).

> Download Your Free Barcode Template <

PS: Have anything else to add about barcodes? Feel free to comment below. Want access to even more templates like this one for food businesses? Sign up for our free Food Business Startup Kit here and get immediate access to our food business model canvas template.